CBG’s President was able to arrive on site in five minutes, an advantage of CBG’s new location in Portsmouth, VA.

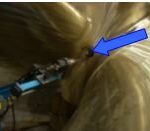

The tap was a 4-inch tap, broken off 5-¾ inch deep in the hole and the prop was due to be picked up in a few days for transport to a ship. A plan was made to disintegrate the tap starting the next day. CBG set up one of their Cammann Inc. portable Metal Disintegrating Machines and using a square electrode, disintegrated the flutes off the broken tap, facilitating the removal of the tap. With no damage to the threads, a new tap was used to complete the threading process and the propeller was ready for shipment ahead of schedule.

Metal Disintegration

4013A Seaboard Court, Suite A-3, Portsmouth, VA 23701